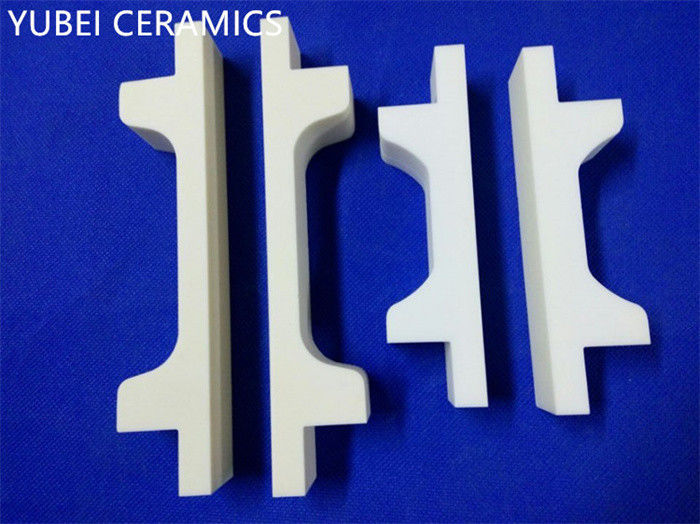

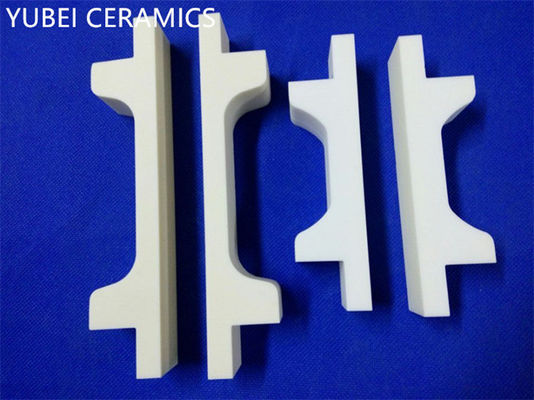

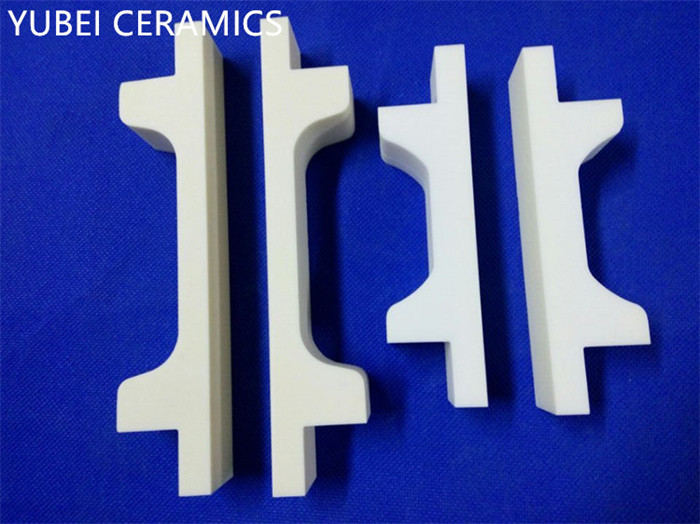

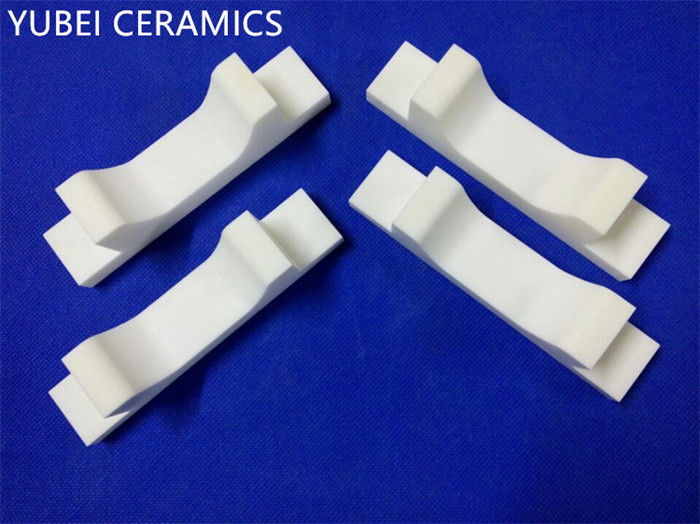

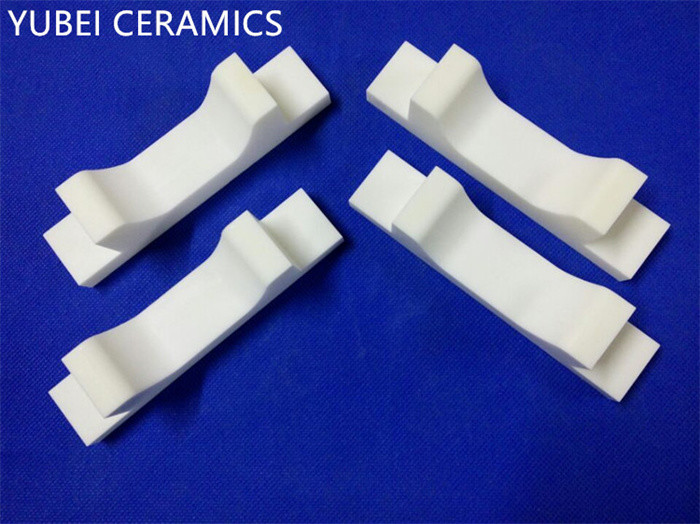

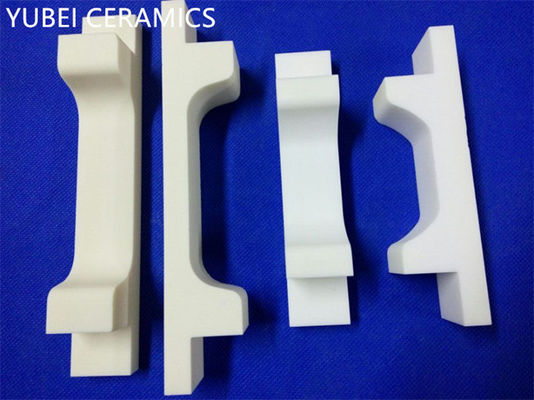

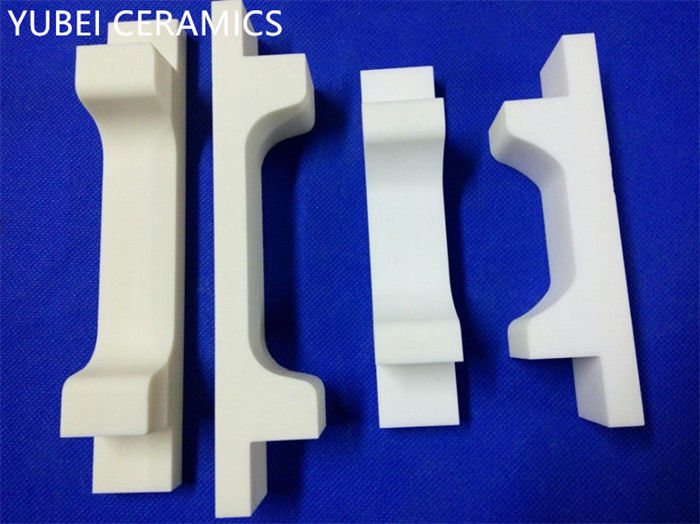

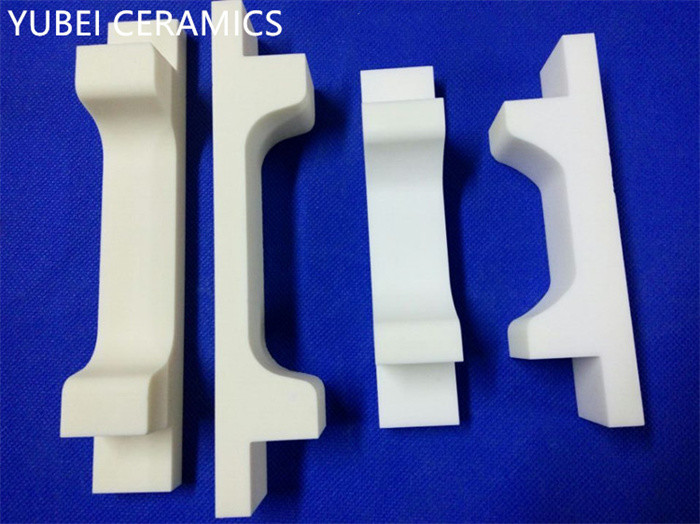

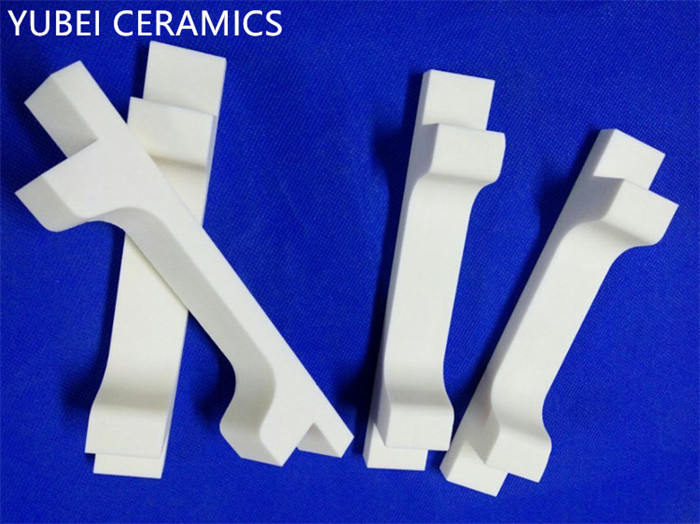

Wear-Resistant Mechanical Alumina Ceramic Industrial Structual Ceramic

Properties of alumina ceramic:

* High Temperature Ability

Alumina ceramics can withstand high temperatures from 1300 to 1650.

* High Hardness and Wear Resistance

The wear resistance of alumina exceeds most common materials. Therefore, it is often used for valve cores, mechanical seals, sharpeners and grinding media.

* Electrical Insulation

Alumina ceramics have very good insulation properties and are often used in the electrical industry. Combined with the ceramic metallization process, it is an important high-voltage insulation material.

* Corrosion Resistance

Alumina ceramics have good alkali resistance, and some specially formulated alumina ceramics have strong acid resistance. Therefore, alumina ceramics have a very important position in the chemical industry.

Specifications:

| Properties |

Item |

Unit |

99% Alumina |

95% Alumina |

| Mechanical Property |

Color |

-- |

Light Yellow |

White |

| Mechanical Property |

Density |

g/cm3 |

3.85 |

3.6 |

| Mechanical Property |

Bending Strength |

MPa |

310 |

300 |

| Mechanical Property |

Compressive Strength |

MPa |

2400 |

2300 |

| Mechanical Property |

Elastic Modulus |

GPa |

340 |

320 |

| Mechanical Property |

Fracture Toughness |

MPam1/2 |

3-4 |

3-4 |

| Mechanical Property |

Weber Coefficient |

m |

12 |

12 |

| Mechanical Property |

Vickers Hardness |

HV0.5 |

1600 |

1400 |

| Thermal Property |

Coefficient of Line Thermal Expansion |

10-6K-1 |

7-8 |

7-8 |

| Thermal Property |

Thermal Conductivity |

W/mK |

29 |

20 |

| Thermal Property |

Thermal Shock Resistance( in water) |

ΔT℃ |

200 |

250 |

| Thermal Property |

Max Working Temperature |

℃ |

1600 |

1500 |

| Electrical Property |

Volume Resistance at 20℃ |

Ωcm |

>1014 |

>1014 |

| Electrical Property |

Dielectric Strength |

V/m |

15X106 |

15X106 |

| Electrical Property |

Dielectric Constant |

εr |

10 |

9

|

99% Wear-resistant Alumina Ceramic

FAQ:

1. Are you a factory?

Yes, we're a factory producing industrial ceramics professinally. Our main products are alumina ceramics, zirconia ceramics and sic ceramics.

2. What's the size of it?

Products are always customized according to drawings or samples. Diameter and height within 500mm are available.

3. What's the price for it?

It depends. Prices are caculated by the drawing size and structure.

4. What's the production process?

Our products are made mainly in cold isostatic pressing, dry pressing and hot press moulding technique. Hot press moulding technique, which was used to shape small and medium size and complicated structure ceramic, is a favorable method.

5. How about the delivery?

Generally speaking, a ceramic production needs about 30 days to finish. Some special products maybe take a longer time. For some simple products, maybe 10-15 days is ok.

6. How's the packing?

The usual packing is cartons, wooden cases, or pallets. Ceramics are fragile products, will use some breakage-proof materials to protect them.

7. Can you do the finish maching?

Yes, we have lathes, grinding machines, milling machines, carves-milling machines to make sure products' accuracy.

8. Which is the nearest port?

Shanghai port is the nearest one from us. It takes about 2-3 hours to get to shanghai port.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!