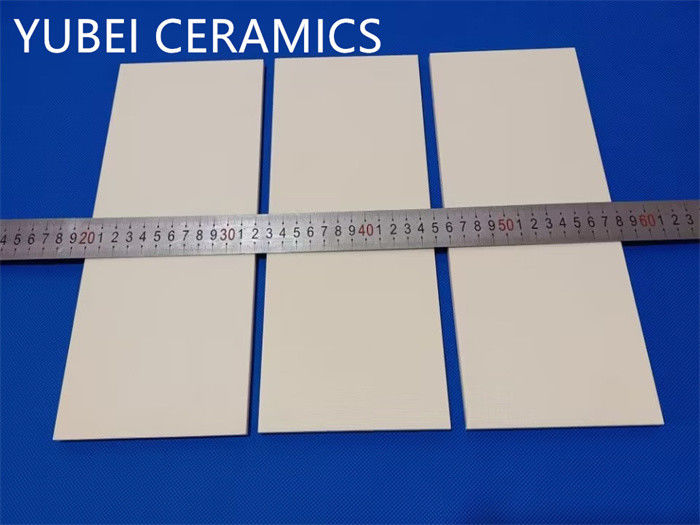

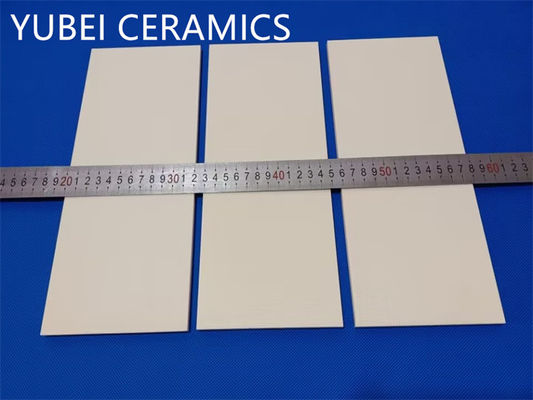

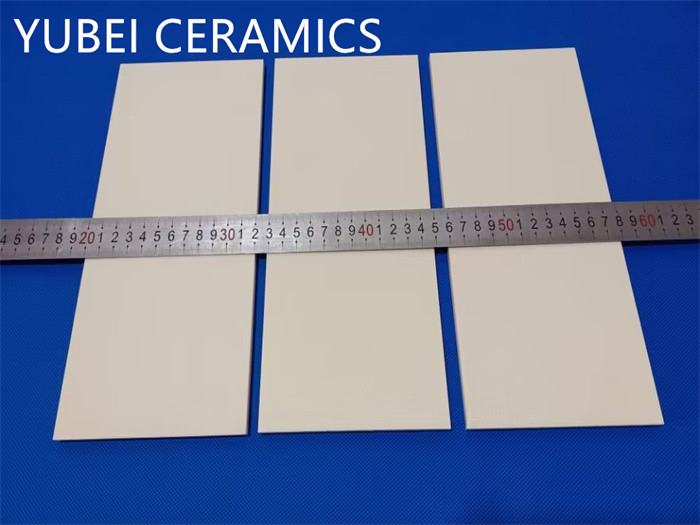

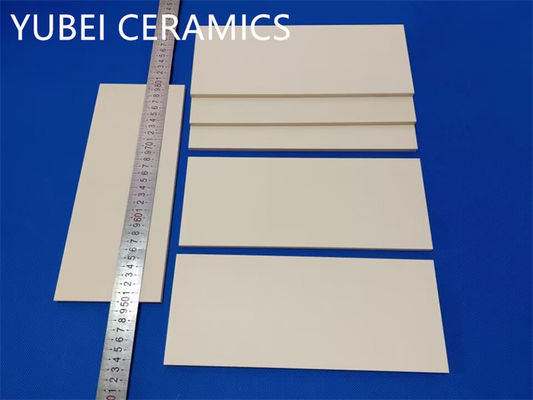

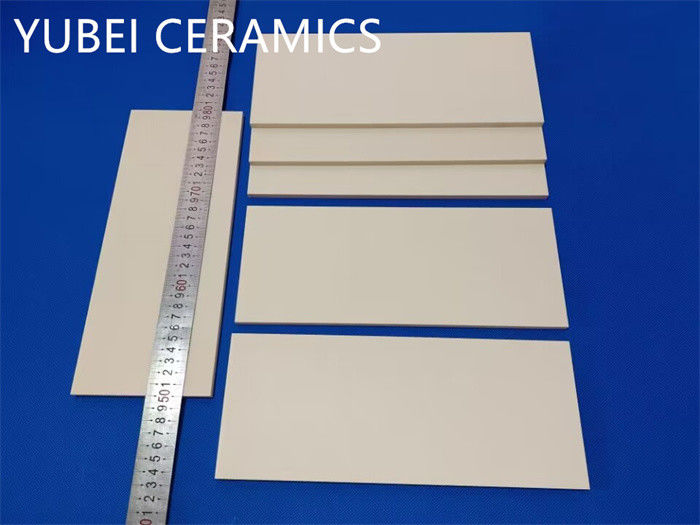

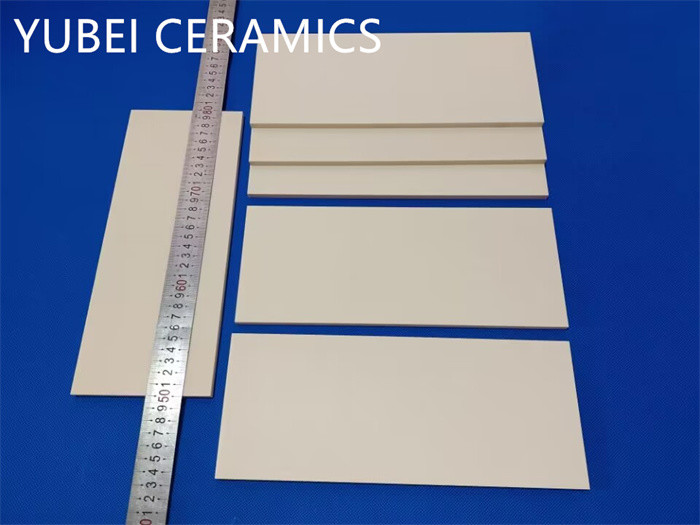

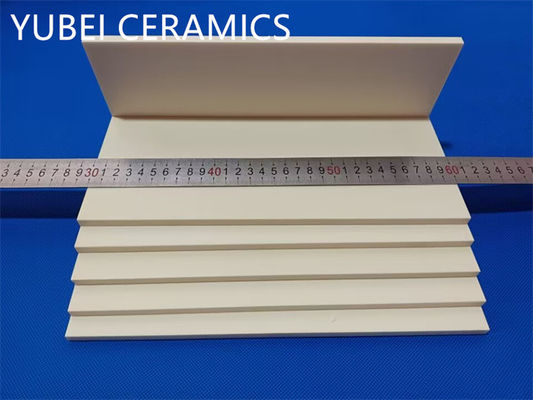

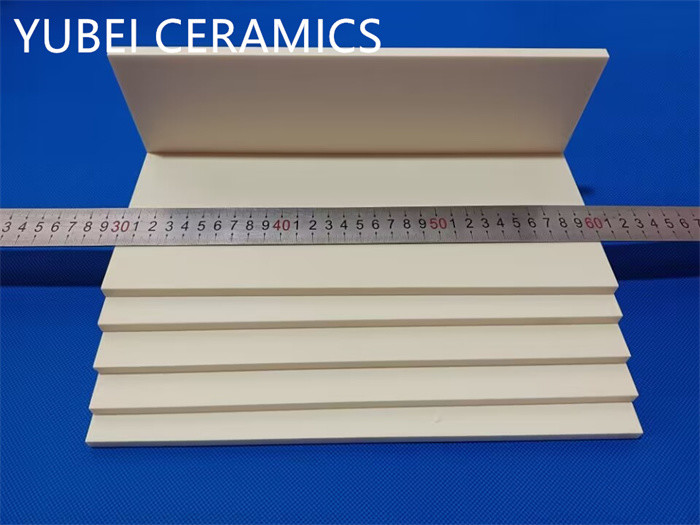

Light Yellow 99% Alumina Ceramic Plate Dry Pressing High Strength

The easiest time to machine alumina ceramic is when it is a green state, before the process of sintering. Green ceramics can be easily machined into different complex structures, but machining at this stage is not always possible, depending upon the part's shape, size and accuracy requirements.

For precision required ceramic parts, they are usually machined after sintering using high-quality diamond-coated tools. These tools help abrate the material away until the desired form of alumina ceramics is created.

The after-sintering machining process will guarantee that alumina ceramic will retain precise dimensions after machining. However, alumina is hard and tough, and this process tends to be expensive and time-consuming.

Manufacturing:

* 99% alumina ceramic material

* Customized according to drawings or samples

* Finish machining

* Fragile proof packing

* 20-30 days deliver time generally

99% Aluminum Oxide Ceramic Plate

FAQ:

1. Are you a factory?

Yes, we're a professional factory manufacturing industrial ceramics, with more than 10-year experience.

2. What's your main products?

Our main products are alumina ceramics, zirconia ceramics and sic ceramics.

3. What's the size of it?

Products are always customized according to drawings or samples. Diameter and height within 500mm are available.

4. What's the price for it?

It depends. Prices are caculated by the drawing size and structure.

5. How about the delivery?

Generally speaking, a ceramic production needs about 30 days to finish. Some special products maybe take a longer time. For some simple products, maybe 10-15 days is ok.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!