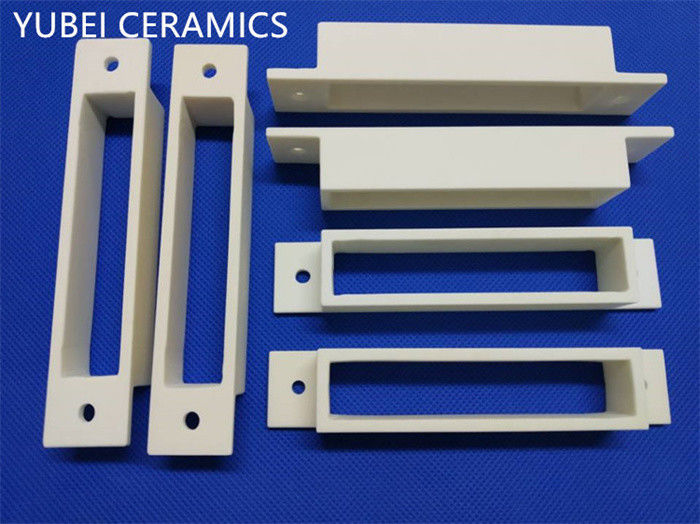

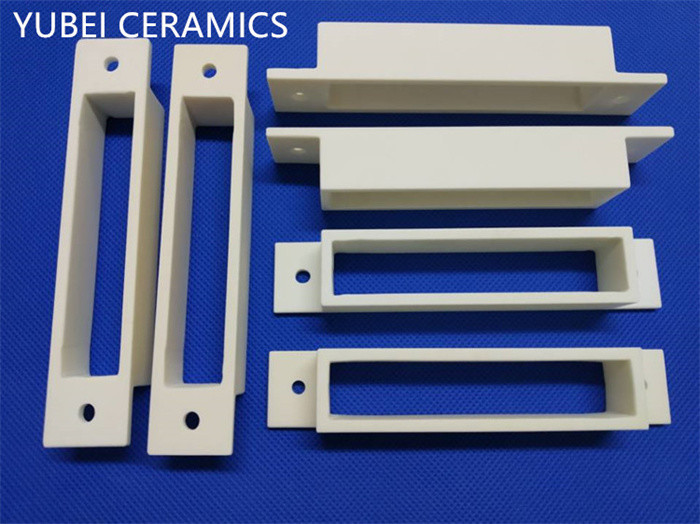

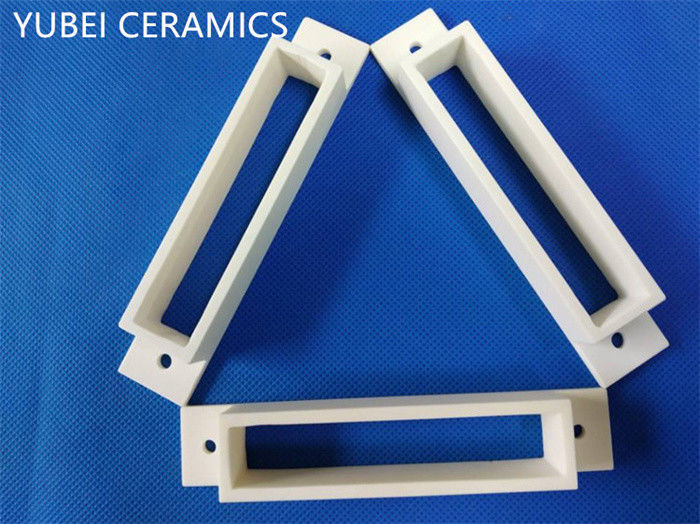

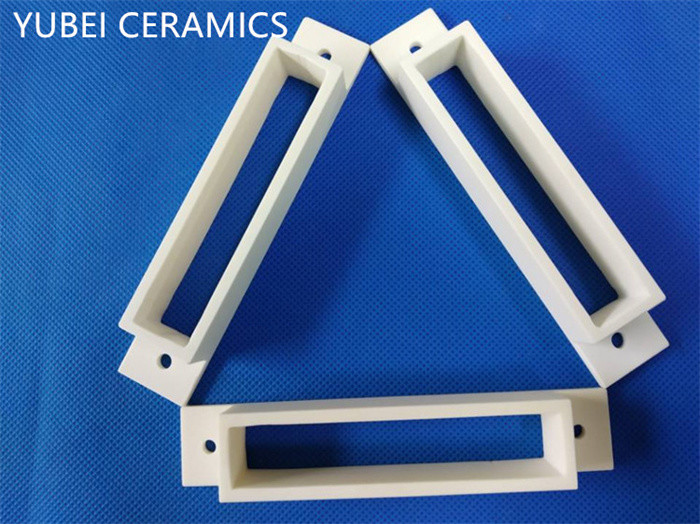

Supply Industrial Structual Ceramic 99% Alumina Ceramic Insulating

The excellent chemical stability of alumina is the major contributor to its high resistance to corrosion. Alumina is also slightly soluble in strong acid (such as hot sulfuric acid and the hot HCl and HF also have some corrosive effect.) and alkaline solutions, but does not dissolve in water. Pure alumina can resist chemical corrosion, making pure alumina the main choice for engineering components in several industrial applications. Its resistance to corrosion by chemicals has been shown to be due to its low solubility in those chemicals.

The introduction of additives can enhance the physical and chemical properties of alumina. These additives, combined with different production processes, can help in the production of alumina ceramics of varying sizes and shapes.

Manufacturing:

| Size |

Customize by drawings |

| Material |

95% or 99% alumina |

| Lead time |

30 days |

| FOB port |

Shanghai port |

| Packing |

Carton, wooden case, pallet |

99% Alumina Ceramic

Packings:

FAQ:

1. Are you a factory?

Yes, we're a factory producing industrial ceramics professinally. Our main products are alumina ceramics, zirconia ceramics and sic ceramics.

2. What's the size of it?

Products are always customized according to drawings or samples. Diameter and height within 500mm are available.

3. What's the price for it?

It depends. Prices are caculated by the drawing size and structure.

4. What's the production process?

Our products are made mainly in cold isostatic pressing, dry pressing and hot press moulding technique. Hot press moulding technique, which was used to shape small and medium size and complicated structure ceramic, is a favorable method.

5. How about the delivery?

Generally speaking, a ceramic production needs about 30 days to finish. Some special products maybe take a longer time. For some simple products, maybe 10-15 days is ok.

6. How's the packing?

The usual packing is cartons, wooden cases, or pallets. Ceramics are fragile products, will use some breakage-proof materials to protect them.

7. Can you do the finish maching?

Yes, we have lathes, grinding machines, milling machines, carves-milling machines to make sure products' accuracy.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!