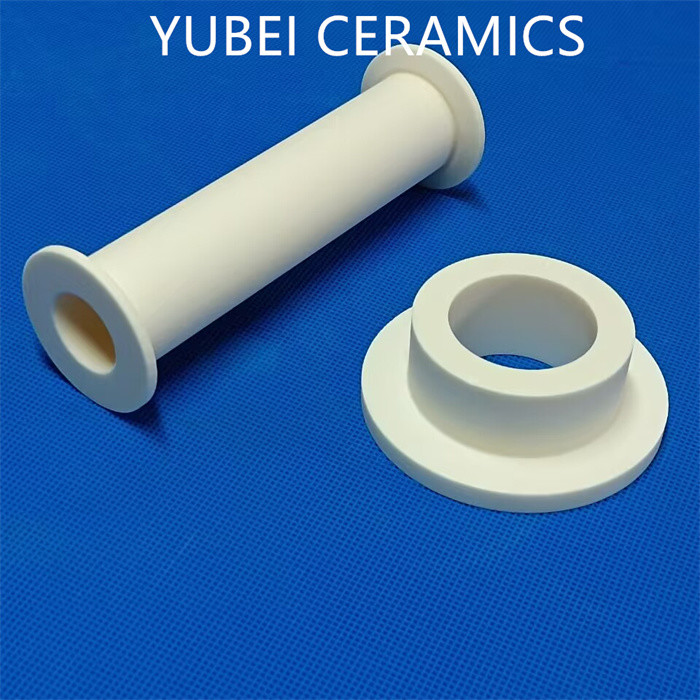

Product Description:

Alumina Ceramic Material (Aluminum Oxide Ceramic) is an extremely hard, high-performance ceramic material made from aluminum oxide (Al2O3). It has a high thermal conductivity (20-30 W/m.K), a density range of 3.6-3.9 G/cm3, good abrasion resistance, and a maximum operating temperature of 1600°C. Its compressive strength can range from 2000-2500 MPa.

Alumina ceramic material properties are very desirable due to its excellent wear resistance, high melting point, high hardness, and its ability to withstand harsh environmental conditions. Alumina ceramic material is ideal for applications in harsh or abrasive environments, due to its superior resistance to abrasion, corrosion, heat, and oxidation.

Features:

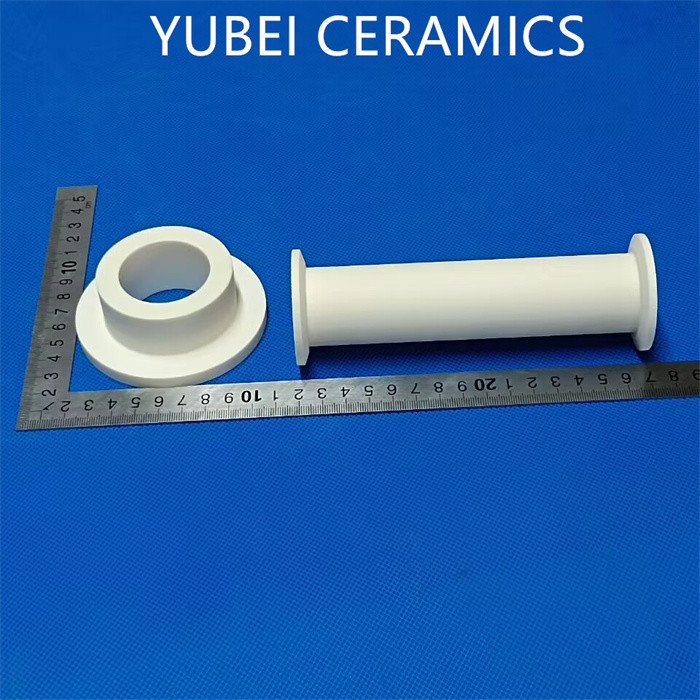

- Product Name: Alumina Ceramic Parts

- Corrosion Resistance: Good

- Material: Alumina Ceramic

- Density: 3.6-3.9 G/cm3

- Abrasion Resistance: Good

- Compressive Strength: 2000-2500 MPa

- Keywords: Aluminum Oxide Material, Alumina Oxide Material, Aluminum Ceramic Material

Applications:

Aluminum Ceramic Material – China YUBEI Ceramic Factory

Aluminum oxide ceramic, or alumina oxide material, is a high-quality ceramic material. It has a wide range of applications due to its unique physical properties. It has a density of 3.6-3.9 G/cm3, a hardness of 9 Mohs, a compressive strength of 2000-2500 MPa, good thermal shock resistance, and a thermal expansion of 7-8 x 10-6/K.

It can be used for a variety of industrial purposes, particularly in areas that require excellent wear resistance, excellent thermal shock resistance, and excellent electrical insulation. It is widely used in the medical, electrical, and automotive industries. It is also used in the production of parts for engines, bearings, and valves. Additionally, it is used for a variety of wear-resistant and corrosion-resistant applications.

Aluminum oxide ceramic is known for its excellent thermal shock resistance and thermal expansion. It is also known for its excellent electrical insulation, making it a great choice for a variety of applications. Additionally, it is an excellent choice for applications that require wear resistance and corrosion resistance.

Aluminum oxide ceramic has a wide range of applications due to its unique physical properties. It is an excellent choice for a variety of industrial applications and is known for its excellent wear resistance, thermal shock resistance, and electrical insulation.

Customization:

Alumina Ceramic Material Customized Service

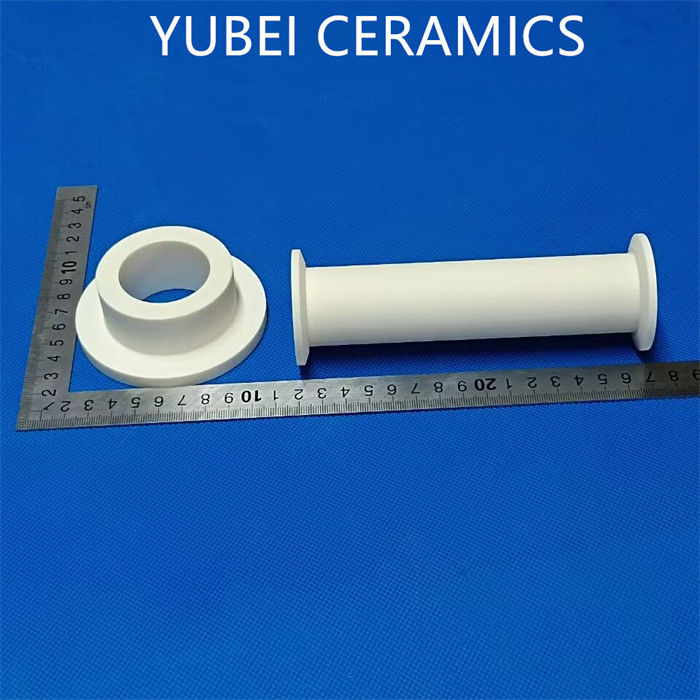

YUBEI ceramic factory offers custom-made Alumina Oxide Ceramic Material Parts. Products can be made according to customers' specific drawings or sizes. Generally speaking, diameters within 500mm, length within 700mm are available.

More details provided, more accurate and best prices can be quoted.

Packing and Shipping:

Alumina Ceramic Material Packaging and Shipping:

Alumina Ceramic Parts are typically packaged in stong cartons or wooden cases or pallets. The packages should be labeled with a warning label to indicate the product is fragile.

Depending on the size and weight of the material, shipping may be done through traditional carriers such as UPS, FedEx, or DHL. The exact shipping method should be determined by the customer, depending on their preferences and budget.

FAQ:

- Q: Are you a factory or trading company?

- A: YUBEI Ceramic factory is a professional industrial ceramic manufacturer with more than 10-year experience. Main products include various of alumina ceramic parts, zirconia ceramic parts, and sic ceramic parts.

-

- Q: What are the characteristics of Alumina Ceramic Material?

- A: Alumina Ceramic Material has high hardness, wear resistance, high temperature resistance, and corrosion resistance.

-

- Q: What is the application of Alumina Ceramic Material?

- A: Alumina Ceramic Material is widely used in many fields, such as aerospace, medical, chemical, electronics, machinery, etc.

-

- Q: What is the advantage of Alumina Ceramic Material?

- A: Alumina Ceramic Material has superior insulation and thermal shock resistance as well as good mechanical strength.

-

- Q: What is the size of Alumina Ceramic Parts?

- A: Alumina Ceramic parts are available in different sizes and shapes according to the needs of customers. Products can be custom-made.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!